|

Complete QC Manual

Quality Assurance

Our inspection system procedures assure conformance

to contract requirements.

The provisions incorporated hereafter are in accordance

with MIL-I-45208A. Unless otherwise requested, the order of precedence for

contract requirements shall be:

1) Purchase Order

2) Drawings

3) Supporting Specifications

This shall apply to all orders requiring the application

of MIL-I-45208A.

|

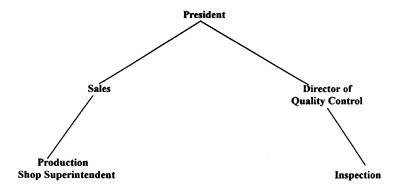

Organization Chart

|

Authority of Quality Control

Inspection Department has the authority to place

stop orders on production where deviations from quality control standards

have occurred. At this time quality control director and production control

will make necessary corrections.

|

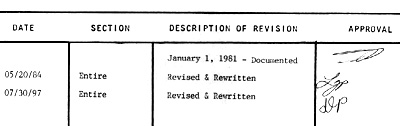

Revisions

All requests for revisions to our quality control

standards reviewed by Quality Control for applicability and adherence to

appropriate specifications.

Revisions will be documented, appended and initialed

by Quality Control.

A complete review of our quality control system will

be conducted annually to assure compliance with applicable specifications

and so noted under the revision control appendices.

|

Revision Record

|

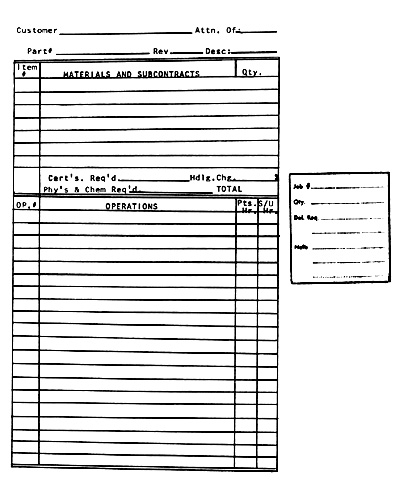

Manufacturing Operations

The purpose of this document is to identify work

in process, sequence of operations, operator, inspection documentation and

special instructions.

One Manufacturing Operations Sheet is issued for

each production lot.

The individual operator and/or inspector is responsible

for the entries required for each operation.

Each operation will be subject to a First Article

inspection and in-process inspections as deemed necessary. The product will

be subjected to a Final inspection and documented on the Manufacturing Operations

Sheet (see Sample Plan for quantity.)

The completed Manufacturing Operations Sheet is maintained

in the customer file with the drawing, certifications, specifications and

other pertinent data.

|

Manufacturing Operations Sheet

|

Document Change Control

Drawings and specifications are filed by customer

name.

Quality Control shall be responsible for assuring

that the correct drawings and specifications of the required revision accompany

the released Manufacturing Operations Sheet and are made available for use

by production and inspection.

Quality Control shall be responsible for making changes

received from the customer and assure the obsolete drawings/specifications

are removed and clearly identified as obsolete.

When a change is put into effect the Manufacturing

Operations Sheet must be revised, dated and initialed and the product in

process must be reviewed to determine the effectivity of potential rework

or separation. Special instructions on the Manufacturing Operations Sheet

shall denote proper action.

All drawings, specifications, Manufacturing Operations

Sheets, certifications and other pertinent data shall be returned to the

customer file folder upon completion of the finished product.

|

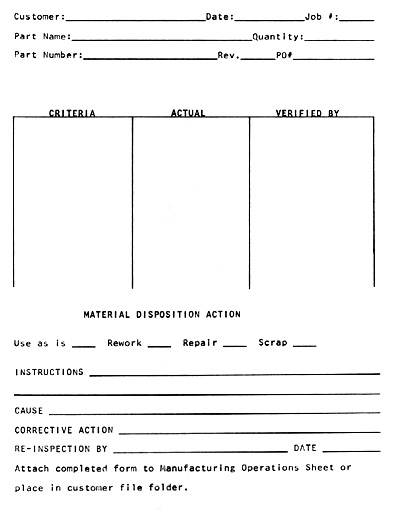

Corrective Action

This procedure details the method of securing corrective

action to prevent a repeated discrepancy/rejection. There are two types

of action required.

IN-HOUSE CORRECTIVE ACTION:

Discrepancies caused internally, parts having been rejected

by inspection or returned from the customer.

VENDOR CORRECTIVE ACTION:

Discrepancies of material, parts or processes as

received

from a vendor.

IN HOUSE C.A.R.: When a rejection occurs during the

in-house operations or hardware is returned from the customer as rejected,

the IN-HOUSE C.A.R. form will be completed and filed in the customer file

folder or attached to the Manufacturing Operations Sheet in process.

VENDOR C.A.R.: When material, parts or processes

are rejected at receiving inspection, a duplicate VENDOR C.A.R. form will

be initialed, original to vendor, duplicate to follow-up. Upon receipt of

acceptable VENDOR C.A.R., the duplicate will be pulled and filed in the

vendor file.

|

In House Corrective Action Request

|

Vendor Corrective Action Request

DATE: __________

TO:

ATTN:

REF. P.O.#:

The following discrepancies have been documented

against the referent purchase order by our Receiving Inspection and require

Corrective Action.

Signed: _________________________

ACTION taken to prevent recurrence: ________________________________________

_______________________________________________________________________

_______________________________________________________________________

BY: __________________________Position:_________________Date:

_____________

*Please detail your corrective action and return

to our inspection department

within 15 days.

|

Material Storage

All material shall be clearly identified upon receipt

with the following information:

Type of material

Customer P.O.#

All material shall be stored in a controlled manner

and in bins or racks to prevent damage.

When a partial quantity is released it will be accompanied

with a Manufacturing Operations Sheet and the remaining material shall maintain

proper identification.

Periodic surveillance of the material storage shall

be performed by the inspection personnel assigned. Any discrepancy will

be reported to the area supervisor for necessary corrections.

|

Non-Conforming Material

The inspection department shall be responsible for

identifying any and all discrepant material and shall separate discrepancies

from the conforming parts.

Identification of discrepant material shall be positive

and clearly shall indicate the rejection cause. Non-conforming Material

shall be segregated in a separate "Hold Area" until disposition

by M.R.B.

Disposition of non-conforming material shall be made

by authorized personnel only. Only inspection personnel may release material

after satisfactory corrective action has been taken.

|

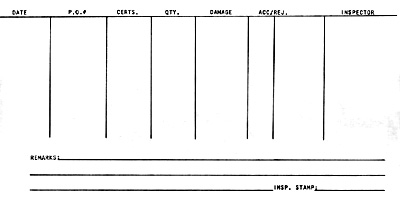

Receiving Inspection

All sub-contracted parts, material or processes shall

be subjected to a receiving inspection.

A receiving inspection log shall be maintained to

record the activity and actions by receiving inspection.

The following steps are to be adhered to in performing

receiving inspection.

1) Obtain copy of P.O., drawings and/or specifications.

2) Log date and Purchase Order Number.

3) Inspect material for certifications.

4) Inspect material for quantity and any physical

damage.

5) Inspect material for criteria (dimension, processes,

etc.)

6) Log accepted or rejected.

7) Identify material (see material storage or issue

C.A.R.).

8) Store material, file certifications in customer

file.

The quantity of parts to be inspected will be consistent

with the sampling instructions of this manual.

|

Receiving Inspection Log

|

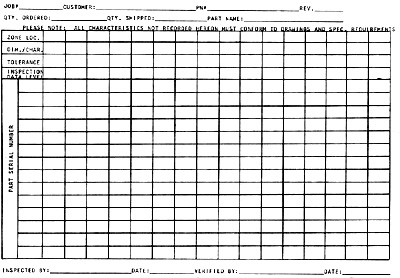

First Article Inspection

A first article inspection shall be performed on

all quality program production orders. The first article shall be noted

on the Manufacturing Operations Sheet. The first article shall be recorded

on an inspection form, to be maintained by Quality Control. All records

are to be kept on file in the Quality control area.

The first article must be acceptable prior to the

release for production to be run for that operation. This may consist of

one or more characteristics as noted on the Manufacturing Operations Sheet

and includes all operations up to the prior inspection.

Correction of operations to produce an acceptable

first article do not require a formal corrective action.

|

In-Process Inspection

If the production run consists of more than 50 parts,

an in-process inspection will be performed at a rate designated by Quality

Control. The inspection will be based on the complexity and tolerance of

the part.

This inspection shall be noted on the reverse side

of the Manufacturing Operations Sheet. All in-process inspections will be

so noted. The information required is as follows:

CRITERIA

PIECE #

ACC/REJ

DATE

BY

The inspected parts will be identified as acceptable

or unacceptable so that no co-mingle will occur in the production run.

If a reject is found during an in-process inspection,

the lot will be 100% inspected for that criteria and the parts rejected

will be segregated and identified as non-conforming material.

This must be so noted on the reverse side of the

Manufacturing Operations Sheet and the foreman notified immediately.

|

Final Inspection

A final inspection shall be performed on all completed

parts using the sampling plan as reviewed earlier. This sampling plan meets

MIL-STD-105.

All rejected parts will be segregated and identified

for proper action by authorized personnel.

A note on the Manufacturing Operations Sheet shall

indicate final inspection performed, quantity accepted and shall be dated

and initialed by the performing inspector.

Final inspection includes verification of all requirements

on the Purchase Order, drawings and applicable specifications.

|

Inspection Record Sheet

|

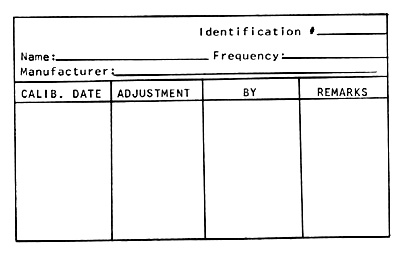

Inspection Equipment Calibration

All inspection measuring devices and control instruments

shall be calibrated at regular intervals sufficient to assure the required

accuracy at all times.

A card file will be maintained by Quality Control

to record a calibration record for each device.

Each device will be identified with a numbered sticker

to relate to the calibration card of the particular instrument/device.

Master equipment shall be calibrated by sources capable

of traceability to the National Bureau of Standards.

The Calibration System shall be in accordance with

MIL-C-45662A.

|

Inspection Equipment Calibration Record Cards

|

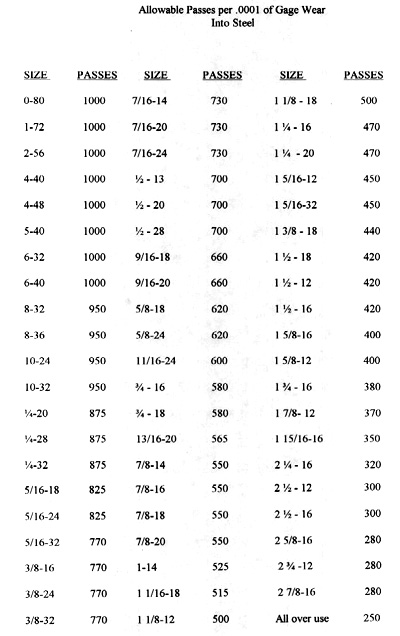

Inspection Equipment Calibration Frequency

NOTE: These designated frequencies are used as the

starting frequency and may be revised as dictated by the frequency of adjustment/repair

required. (See individual calibration cards.) In no case will 12 months

be exceeded.

Micrometers (all types) ----------1 month

Dial/Vernier Calipers -----------3 months

Thread Plug Gages ---------------3 months or number

of passes

Thread Ring Gages ---------------3 months or number

of passes

Dial Indicators ---------------------3 months

Plain Plug Gages ------------------6 months

Precision Pin Gages --------------6 months

Drill Blanks -------------------------6 months

Precision Height Gages ----------6 months

Electronic Height Gages ---------6 months

Gage Blocks -------------------------12 months

Surface Plates -----------------------12 months

End Standards -----------------------12 months

Optical Comparators --------------12 months

Protractors ---------------------------12 months

Vee Blocks ---------------------------12 months

Parallels ------------------------------12 months

Angle Plates -------------------------12 months

Precision Squares -----------------12 months

Sine Bars ----------------------------12 months

|

Thread Gages

|

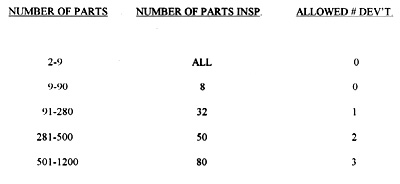

Sampling Plan

This sampling plan is applicable to receiving inspection,

in-process inspection and final inspection.

The chart, as follows, is based upon normal operations

assuming the equipment is capable of holding the required tolerances. In

the event there are other circumstances such as tight tolerances, difficult

material or operations that are historically difficult to produce, the inspector

will initiate a tighter inspection plan as required. The customer may establish

the sampling plan as per purchase order and specification requirements.

If a tightened sample plan is determined necessary,

this shall be noted on the reverse side of the Manufacturing Operations

Sheet.

|

Sample Plan Table

|

This page is best viewed with a screen

resolution of 800x600 or higher with Netscape 4.0 or Internet Explorer 4.0.

|